The 3PE steel pipe external anti-corrosion coating is a composite structure consisting of a base layer of epoxy powder, an intermediate layer of adhesive, and an outer layer of polyethylene. This structure features high mechanical strength, excellent electrical insulation properties, high mechanization in production lines, stable process parameters, and environmental friendliness.

The 3PE steel pipe anti-corrosion production line is specifically designed for applying anti-corrosion coatings to steel pipes of various diameters in factories. It is widely used in engineering construction fields such as heating, gas, and oil fields. The production line consists of a base layer of epoxy powder, an intermediate layer of adhesive, and an outer layer of polyethylene, offering multiple advantages.

Three-Layer PE Anti-Corrosion Structure Parameters for Pipelines

First Layer: Epoxy powder (FBE), thickness > 120μm

Second Layer: Adhesive (AD), thickness 170-250μm

Third Layer: Polyethylene (PE), thickness 1.8-4.2mm

These three materials are fused together and firmly bonded to the steel pipe, forming an excellent anti-corrosion coating.

Features

1. Cost Reduction

High sealing performance minimizes energy consumption, lowers operating costs, and protects the environment.

2. Long Service Life

Easy and fast installation with a lifespan of up to 30-50 years.

3. Excellent Impact Resistance

Performs well under low temperatures with low PE water absorption.

4. Superior Anti-Corrosion Performance

High epoxy strength, flexible adhesive, and low PE water absorption ensure reliable corrosion protection with a simple and cost-effective process.

5. Fully Automated Processing

A PLC intelligent control system with integrated sensors enables full automation, stable performance, and high production accuracy.

Product Parameters

| Production Range |

50-4200mm |

| Processing Capacity |

≤350м²/h |

| Cleaning Grade |

Sa≥2.5 |

| Materials Used |

FBE powder, adhesive, polyethylene |

| Coating Areas |

Internal, external |

| Production Capacity |

30 sets/year |

| Base Layer |

Steel |

| Coating Structure |

FBE, 2LPE, 3LPE |

Applications

The three-layer polyethylene anti-corrosion coating, as an advanced outer protective layer for buried pipelines, is widely used in the anti-corrosion of fluid transmission pipelines such as oil and gas pipelines, urban gas pipelines, and water supply pipelines. The 3-layer PE anti-corrosion coating enhances the mechanical properties of the pipeline, featuring high electrical resistance, waterproofing, wear resistance, and aging resistance.

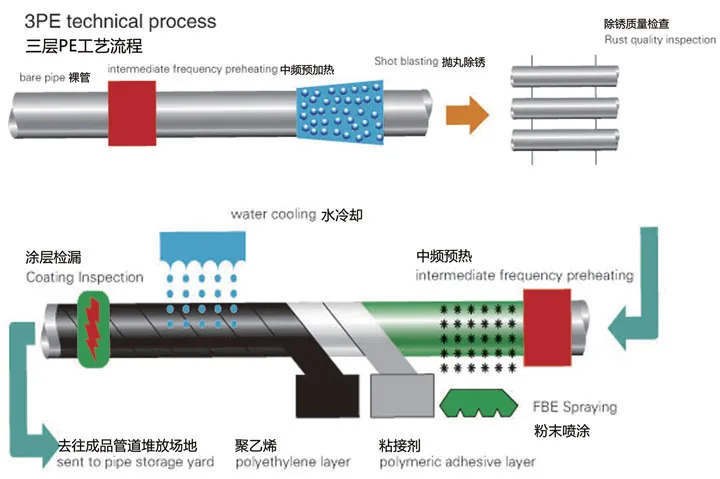

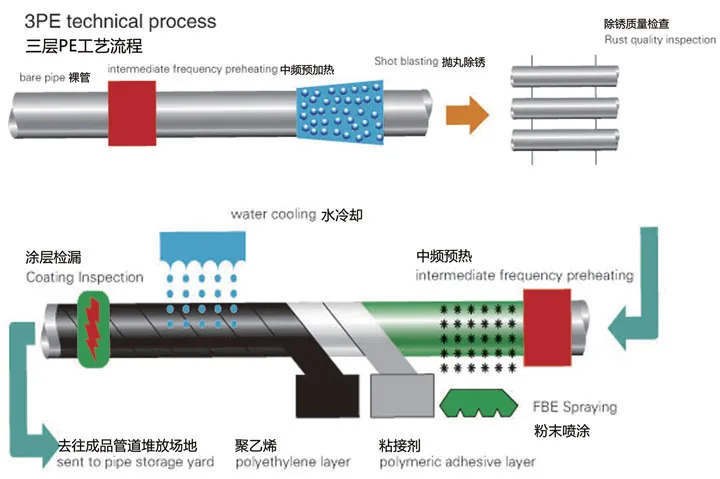

Technological processes

Loading Pipe → Spiral Conveying Pipe → Rust Removal → Intermediate Frequency Heating → Epoxy Powder Coating → Outer Layer Polyethylene Adhesive Coating → Cooling and Spraying → Spiral Conveying Pipe → Pipe End Grinding → Unloading Pipe

Our Advantages

1.Awarded as the First (Set) Technical Equipment in Shandong Province

2.High Speed, High Efficiency, and Stable Performance

3.Highly Automated and Intelligently Designed to Reduce Labor Requirements

4.Over 70% of Products Exported to Europe, the Middle East, Central Asia, Africa, Russia, and Other Regions

5.High Market Share and Strong Industry Reputation

Company Profile

Qingdao Huashida Machinery Co., LTD, is a manufacturer of series of plastic pipe machines, municipal pipe machines, pipe insulation&anticorrosion machines, and pipe jointing&anticorrosion materials, with 21 years of production experience.

Our main products are:

1. HDPE jacket pipe for pre-insulated pipe Production Line (110-2000mm)

2. Rigid pre-insulated pipe Production Line

3. Flexible pre-insulated pipe(PERT) production line

4. Steel pipe FBE/2LPE/3LPE anti-corrosion coating line

5. Steel pipe derusting line

6. PE pressure pipe/Water Gas supply pipe production line

6. PP/PE plastic board/sheet/geomembrane production line

7. NBR PVC Thermal insulation tube/plate production line

8.Pipeline anti-corrosion materials and instruments: heat shrink joint coating sleeve, electro-fusion weldable joint sleeve, portable welding gun(extruder), PE PP welding rod. We have been working with more than 400 overseas customers and exporting our products to Kazakhstan, Uzbekistan, Iran, Turkey, Russia, Nigeria and other countries.

Our team

Our team

Delivery

Delivery

Exhibition

Exhibition Certifications

Certifications

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!